Transparent Traceability and EPR Compliance for Multilayer Flexible Packaging.

Transparent Traceability and EPR Compliance for Multilayer Flexible Packaging.

Multilayer flexible packaging, such as snack bags, sachets, and toothpaste tubes, … is often considered difficult to recycle due to its composite structure and low recovery value. However, through a controlled collection, traceability, and recycling model, these materials can be managed transparently while fully meeting Extended Producer Responsibility (EPR).

Post-consumer multilayer flexible packaging is collected from schools, apartments, and markets that participate in source separation. At the point of generation, snack packaging and other flexible multilayer materials are sorted separately and consolidated at Green Points operated by GRAC. All collected volumes are recorded in a digital material-tracking system to ensure transparency from the earliest stage.

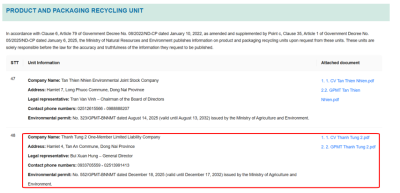

At each Green Point, materials are received, weighed, and documented through tracking records into the Grac application. These records form the basis for managing material flows and enabling traceability across the collection–transport–recycling chain. Collected multilayer packaging is periodically transferred to Thanh Tùng 2 Co., Ltd., a recycling facility officially registered and listed on the National EPR Portal in accordance with current regulations.

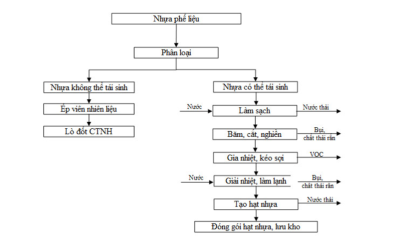

At the recycling facility, plastic waste is sorted by recyclability. Recyclable fractions are processed through mechanical recycling, including sorting, cleaning, shredding, and pelletizing to produce recycled plastic resin. Non-recyclable fractions are converted into refuse-derived fuel pellets and treated at licensed hazardous-waste incineration facilities in compliance with environmental standards. Throughout operations, emissions such as wastewater, dust, solid residues, and VOCs are monitored and managed at each processing stage.

The plastic recycling technology process at Thanh Tung 2 includes the following stages:

Outputs from the recycling process include recycled plastic pellets and downstream recycled materials, such as plastic boards for display, design, and creative applications. The entire chain, from generation at schools, collection by GRAC, transfer to the recycling facility, and final processing, is documented through records and digital tracking data to ensure transparency, traceability, and support EPR/ESG reporting for stakeholders.

Instead of relying solely on financial contributions to the Vietnam Environmental Protection Fund (VEF), which can cost more than approximately USD 0.45 per kilogram of packaging based on the applicable Fs coefficient, companies can adopt a physical recovery-and-recycling approach. This model converts hard-to-recycle flexible packaging into new recycled materials and products with continued value, while fulfilling EPR obligations based on verified recycling volumes.

By combining traceable collection with compliant recycling, this approach helps companies meet EPR requirements, optimize compliance costs, and increase material value within the circular economy. It also reduces reliance on financial contribution mechanisms and strengthens transparency across the entire packaging recovery and recycling system.